In a French village the source one day did not yield any more water. After some searching and digging they found a supply line. This was followed a long way, until leading to a pump. That delivered water for so long that no one knew she was there. She was restored, and the ’source’ functioned again.

The only – of a dozen - remaining French manufacturer Walton since then paint his pumps striking red.

There are several stories of pumps that continue to work for decades long. In the castle Ménardière (Deux - Sèvres) there is one of more than 120 years old, that after a slight restoration still works. Purely on hydropower, without electricity or diesel, 24/7.

There are several stories of pumps that continue to work for decades long. In the castle Ménardière (Deux - Sèvres) there is one of more than 120 years old, that after a slight restoration still works. Purely on hydropower, without electricity or diesel, 24/7.

Joseph Montgolfier (also (co) inventor of the hot air balloon) developed ’le belier hydraulique’ in 1796. The pump is based on the principle of the ’ram’ discovered by John Whitehurst in 1772. The (hydraulic) ram (pump) is called ram pump or water hammer.

A water hammer is a pressure surge in a closed liquid pipe caused by the abrupt stop or start of the flow, e.g. by quickly closing a tap or valve. The energy of the flowing water is then converted into a high-speed pressure wave which passes through the conduit as a result of the sudden current change. Water hammer can break pipelines or damage equipment.

This can be avoided or reduced using flexible pipes, or slowing down the speed of liquid, setting of a bypass; or placing air intake valves and pressure relief valves, which in case of over-or under pressure, let in air, or fluid out of the conduit; lowering the shutter speed, etc.

That’s how (industrial) water suppliers avoid cracks in long transport lines by water hammer. At home the blow of the water hammer can be heard effectively.

The ram uses this energy to pump water to a higher level. It is easy to make (even in developing countries and remote areas). It only has two moving parts: check valves you can find in every decent do-it - yourself (or plumbing) shop. Additionally needed is some decay between water buffer (river...) and the lower place for the pump that hammers a little water each time to a much higher altitude, up to thirty times higher. Water thus may be rammed tens of meters high and 100s of meters far.

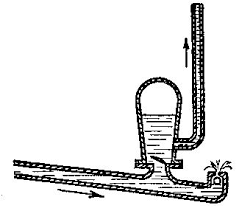

Construction (principle)

The ram consists of a small tubing in F form. F that we lay flat on her back, legs up, tail to the right (to make the description visual). On the most left leg is a check valve shutting this output as the coming water that is supplied through the tail on the right side, has built up sufficient speed and power to do so. The supply happens via a steel pipe as straight as possible.

In the middle leg also a check valve that only opens up is assembled. With on top the pipe that brings the water upward.

Operation

The flow of water strikes the final valve. The pressure builds up and the shock wave hits and opens the second valve and squeezes up some water. This reduces the pressure in the system for a moment, making the final valve is opened again, the water is flowing again, pressure builds up through the open valve, (temporarily) flows away, and slams this door again, etc. The water pressure remains endlessly pressing up bits of water about 1 to 2 times per second.

Sufficient water must flow in fast enough (full supply pipe) to operate the valves cycle, but not so fast that it cannot built up pressure.

The inclination of the supply line would be best in the following ratio: with the pump placed 1 meter below (the (inlet opening of) the water supply) on a (horizontal) distance of (5 to) 5.6 meters. A height of 150 cm is always recommended.

Every good design will work, but a well-adjusted stroke cycle, shutter speed (heavier or suspension valve), tube diameters etc improves the efficiency.

For supply and ram use the same diameter. With a larger supply the knock has to move a heavier weight.

Improvements

Place filters at the supply so that no dirt can flow between the valves.

Make sure that the input is always under enough water so that no air can get in. If necessary, dig a waterhole next to the river. Or two, one in which dirt and sludge primary can precipitate.

Anchor the ram firmly on a stable surface to prevent loss of energy in moving the unit.

The best result (most pressure) you get with the final valve vertical, straight up, with the opening up.

Use one piece steel tubes for the ram and input. Softer plastic material absorbs some of the shock wave.

If you place a pressure gauge, assemble a stopcock under it. Otherwise it’s guaranteed that it will break on constant use.

Keep the intake pipe as straight as possible, and of equal diameter. Make (if necessary) bends as wide as possible and gradually.

You can place multiple pumps in parallel.

You can mount a breather 10-20 cm before the ram on the horizontal delivery pipe.

A stopcock on the inlet and outlet is convenient to test improvements and to perform repairs.

! Connect the up pumping valve with an air chamber or pressure vessel, on which the delivery pipe is below. (E.g. place a T above the valve, and mount directly above the valve the air buffer, and the transport pipe on the right.) This is an important optimization in which the compressed air absorbs shocks and regulates the current upwards. The compressed air pushes the water upwards. A PET bottle will do, but also (better) a fire extinguisher, or a real pressure vessel. The air pressure chamber preferably has a volume of 20, and better 50 times the volume delivered per pump cycle.

The compressed air will in time be more and more dissolved in the water and disappear with it. This can be prevented by closing in the air in a rubber bag (tire...).

Some (French) schemes show halfway the feed tube an upright (open) monitoring tube. In too short a supply pipe, the pressure wave cannot develop. If it’s too long the shockwaves interfere.

For the supply pipe the ratio of length / diameter (d) is best between 150 and 1000. The length is at least 150 x d, and up to 1,000 x d. If the feed is longer, then mount a monitoring pipe at the maximum length (ending up to 30 cm above the supply level). It brakes and absorbs the shock wave, which would otherwise become too long and slows down the pump pulse of the ram or will interfere.

Efficiency

An energy efficiency of 60 to 80% is feasible. But do not confuse this with the volumetric efficiency. With a feed from 2 meters high and ramming up to 10 meters, 80% of the water is wasted (at 100% energy efficiency). The energy efficiency of 70% on a water return of 20% will ultimately produce 14% efficiency. But because this energy is free, and pumping continues endlessly, this is no problem. Good sizing improves the result.

Flow

The flow supplied is approximately 0.6 x Q x F / E = D

Q is the available water volume (liters / minute) F the level difference between source surface and ram, E the height to pump up and D the water supplied (liters / minute) on top. 0.6 is an efficiency factor that varies. The same pump therefore will provide less water as it should have to push it higher.

Starting the pump

If the exhaust valve at the end is or remains open you should close it manually until the supply is filled with water and air bubbles are escaped. This may take more than 1 minute.

Open (press) the exhaust valve 1, if necessary several (up to 20) times until the cycle repeats itself automatically.

Above the second valve you also can mounted a plunger (piston) that drives e.g. a generator.

In the Philippines, the Dutch engineer Auke Idzenga (and AIDFI) makes since 1980 easy to maintain and cheap copies. For the only moving part, the exhaust valve a simple door hinge is used.

The Hydram is a concrete water hammer pump from Dutch design.

In Australia the Billabong is sold for 1000-2000 €. It can pump water up to 12 meters high.

In streaming water, the flow can also be used to drive a paddle wheel or turbine which makes move a pump permanently too.

(See also <Raising water > in Agriculture and horticulture)

(See also <Archimedes’screw and Jack-screw> in Tools, mechanics)