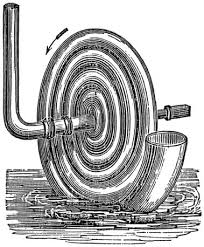

H.A. Wirtz, a pewterer from Zurich, Switzerland would have created in 1746 a spiral pump.

Nowadays, they are easy to make by rolling a flexible hose. Formerly a spiral was made between two wooden or metal discs.

The entrance (on the outside) will be broaden to scoop water.

The entrance (on the outside) will be broaden to scoop water.

The output connects to the rotating shaft. The disk is approximately up to the shaft in the water, so that the outer ring is half-filled with each revolution.

The operation can happen manually (or otherwise ). But commonly blades are placed on the outside of the wheel that rotates by the flowing water.

When using one wheel, you can increase the capacity by assemble balanced one (or more) spirals on each side. With two wheels, you can install multiple spirals in between. For a better balance and smoother pump results, do not place the two spirals inputs at the same height, but facing each other. Multiple inlets your spread equaly.

Because alternating water and air are boasted the system builds up pressure, making you can pump up water under pressure without valves or pistons up to 25 m with a capacity of 1 l / s.

With each rotation, the water moves one level to the center, making each time the enclosed air is further compressed.

The bubbling air gives (in addition to the pressure) extra lift to the water in the discharge pipe.

The most difficult and crucial part is the link between the rotating shaft / collector tube in the center and the stationary distribution pipe. Which must be relatively close to avoid water - and pressure loss as much as possible.

The head appears to be dependent on the number of spirals and the outer diameter of the spiral.

A wheel of 2m with 6 windings pumped water to 8m high, with four windings 6m, and two rings go 4m high.

The volume is dependent on the amount of water that can be taken up and retained on each revolution.

The pressure of the water flowing against the paddles must be sufficient to push the weight of the water in the coil and the whole structure to rotate around.

The drain should not be impeded (too high, closed) otherwise in the coil accumulated air pressure will float water back out. This can also (partly) happen at a high rotational speed.

Advantages of the spiral pump (sometimes called Wirtz- or Barsha pump):

No external power is required

Only one moving part and low maintenance,

Operates 24/7

Low production cost, easy to build

If the coils are not under, but next to each other it also is called a gauge pump. Which are also sometimes used horizontally or at an angle up to 45 degrees, whereby the lifted water is carried out by the extended shaft.