In a worm (screw) and the worm wheel teeth fit into each other. Is the worm driven, the worm wheel will turn slow. For stringed instruments (guitar etc.) that is used in the tuners. The vise works the same way.

A rack and pinion converts the rotary motion of a gear wheel into a linear movement, for example by drive belts and chains.

The rack is a straight bar provided with teeth on one side. With a small gear wheel which engages in here, the rod may be moved in the longitudinal direction.

This is e.g. applied in a corkscrew with two arms, or on a drill press, steering, dyno torch.

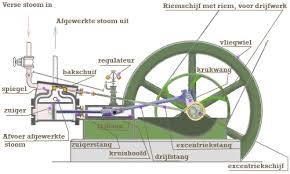

The eccentric does enable a pivoting movement to rotate out of the center and is able to convert it into a reciprocating motion. It is especially known for the rods on wheels of steam locomotives. The treadle of a spinning wheel or sewing machine works the same way.

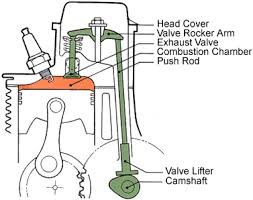

The camshaft can be seen as a shaft with disks that rotate each above a piston. Replace the disk by an oval: the rotating bulge will do the piston moving back and forth. This movement can be used for cutting, crushing, hammering, of presses, punching, pumping.

The wrought iron or steel crankshaft (usually) has three (sometimes 2 or 4) rods at an angle of 120° with respect to each other.

The wrought iron or steel crankshaft (usually) has three (sometimes 2 or 4) rods at an angle of 120° with respect to each other.

Al - Jazari (Mesopotamia, present-day Syria and Iraq) wrote in 1206 his “Book of knowledge of ingenious mechanical devices”. He made the first crankshaft and camshaft that can convert a rotary motion into a back-and -forth, and vice versa!

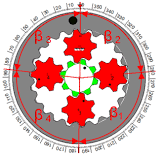

A planet gear (epicyclic) mechanism comprises a gear wheel, to it (above and below) two equal gear wheels, and, the outside fitting around these two an inner toothed gear (or ring gear). With this system a very high transmission ratio can be realized.

A planet gear (epicyclic) mechanism comprises a gear wheel, to it (above and below) two equal gear wheels, and, the outside fitting around these two an inner toothed gear (or ring gear). With this system a very high transmission ratio can be realized.