To transfer movements over a greater distance no gears are used.

A drive belt connects two shafts. Belts produce little vibration and shocks, and so little noise. They are useful for large wheelbase and there is little lubrication needed.

A drive belt connects two shafts. Belts produce little vibration and shocks, and so little noise. They are useful for large wheelbase and there is little lubrication needed.

Belts are not suitable for synchronous drives because they can slip. This can be avoided with toothed belts (timing belts).

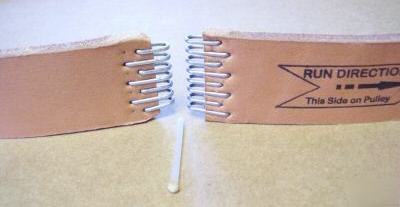

Previously leather thongs were used because of their high friction coefficient. In the ends were knocked special staples. Both ends fitted so as the teeth of a zipper together. With a tendon through it they were attached.

If the belt slipped through the inside of the belt made was stiff again with a resin block. Today, synthetic strings and (rubber) straps are used, sometimes reinforced with steel wire or textile.

With a V- belt greater transmission capacity can be achieved than with a flat belt. The pulleys pull the V-belt tight and prevent skidding. There is a greater gripping surface to the pulleys. The tension on the belt or rope can be improved by a loose wheel with a spring pushing against it, or e.g. by an engine hinged to hang in the belt. His weight then creates tension.

Variable transmission is known of the automatic transmission in cars. A trapezoidal or tapered rubber belt runs over two pulleys, one driven by the motor. A pulley is a rimmed belt wheel with (V-) edges. The pulleys consist of two conical parts, which can slide over the shaft by the rotational speed and springs with respect to each other. As a result, the diameter varies, and therefore also the transmission.