Coolant

In order to cool forged steel typically water (or oil) is used. This also depends on the composition of the material to cool. The thermal conductivity of the cooling fluid can cool work piece faster or slower. Too slow cooling does not give quenching. Too fast cooling can lead to rupture or breakage of the metal.

Thermal conductivity of water = 0.60

Thermal conductivity of oil = 0.17

This means that water can absorb and deliver heat nearly four times as fast as oil, and can absorb about three times as much heat (4.18 to 1.65).

Hardening steel

With manganese steel can be hardened by cold rolling. This is used for train rails. Normally we harden steel with a heat treatment. Depending on the composition of steel, the temperature and the velocity of the cooling; the crystal lattice, the arrangement of atoms in a crystal, will change and the wear resistance and the hardness increase due to the higher internal tensions which then are in the material. (Different crystal lattice structures are referred to as ferrite, pearlite, austenite, martensite, cementite.)

The workpiece is slowly and evenly throughout heated until it has a cherry red color. It is about 770 degrees Celsius. Do not let it overheat and burn. You can see in that case that there is a kind of sparks splashing away.

Cool in a large bucket of cold water (or oil). Stir the steel well into the water, so that no bubbles remain trapped, which locally affects cooling adversely.

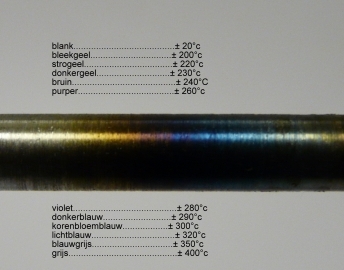

A rule of thumb was used for hardening steel: from cherry red to sky blue. (So first heat to red, then cool to blue in water).