Glass consists predominantly of crystalline silica (silicon dioxide (SiO2), token from sand.

In pure form can be made quartz glass of silica. However, it is still expensive and difficult to work.

Rock crystal (clear quartz) is (almost) perfectly crystallized silica, but no glass.

Rock crystal (clear quartz) is (almost) perfectly crystallized silica, but no glass.

For production and processing are used as softeners CaCO3 and Na2CO3. This lowers the glass transition temperature to 700⁰C.

Plain glass or soda contains 70% SiO2. Various compositions and types, with different properties are possible.

It is strong, hard, transparent, acid resistant but brittle. A fascinating material.

Volcanic eruptions with silica form a dark natural glass known as obsidian, which millennia ago already was used to make arrowheads. The normal melting temperature for silica (about 1800°C) could not be obtained in primitive wood-burning furnaces. It only succeeded after addition of soda ash or potash which lowered the melting temperature to 900-1100°C.

Natural tints are removed by the addition of nitre, manganese or arsenic.

Additions of metals produce different colors.

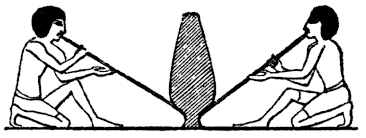

Glass was invented around 3000 BC in Egypt or Mesopotamia. Around 1500 BC, Egyptian craftsmen made glass jars, first as decorative objects. They wrapped this hot, viscous glass around a clay core: the sand core method.

As a flux are sodium or potassium carbonates used. In order to obtain processable glass is also a coagulant needed. For this purpose, lime (CaO) was used. Since 1830, it is assumed that a ratio of about 6 parts of sand (SiO2), 1 part of soda and 1 part of calcium is a good combination.

A mixture of sand or gravel and deicer: lime and soda or potash, is melted at a temperature of 1,400 to 1,500 degrees. A glass furnace was usually fired with beech. The ash was used as potash.